The minimum order quantity for knit-on-demand services is typically 1.

The service is designed to produce fully knitted products only when an order is placed, allowing for on-demand manufacturing without the need for a minimum order quantity. This approach enables businesses and individuals to create, buy, and sell custom knitwear without the burden of holding inventory or committing to large production runs.

Are there any discounts available for bulk orders in knit on demand services

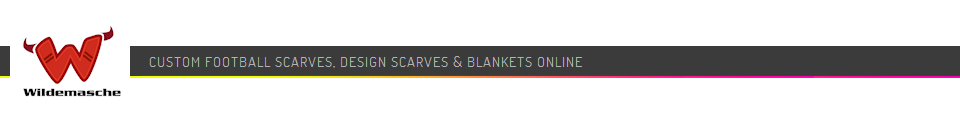

Yes, there are discounts available for bulk orders in knit-on-demand services. For example, Wildemasche, a popular knit-on-demand service, offers discounts for bulk orders on almost all of their products, starting from 2pcs with same design already.

The knit-on-demand service provides a wide range of creative options and seamless designs for businesses, indicating that they offer discounts for bulk orders as well.

Furthermore, knit-on-demand services have reduced the production minimum order quantity from hundreds to 1.

How much discount can be availed for bulk orders in knit on demand services

The specific discount amounts for bulk orders in knit-on-demand services vary depending on product. However, it is common for print-on-demand services, including knit-on-demand services, to offer discounts for bulk orders. Wildemasche, like a lot of other print or knit on demand manufacturers, mentions that all of their products are eligible for bulk discounts. Check out their rates and product variations on their website.

Knitting companies emphasize competitive pricing and the ability to sell at a higher price point when in retail, indicating that they likely offer discounts for bulk orders as well.